Learn how to PRACTICALLY implement an effective zero-cost Brand Protection programme WITHOUT adding incremental cost or complexity to your manufacturing process.

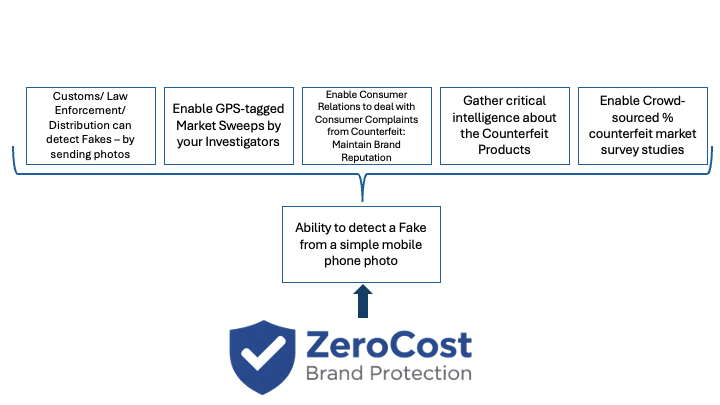

We believe all companies esp. fast moving consumer goods (FMCG) should have a base-level of near zero-cost measures systemically built into the products that enable the great majority of all counterfeits to be detected from a standard mobile phone photo. You then can detect counterfeits in all areas of the supply chain, in near real-time, from customs to investigators to enabling your internal consumer relations department better deal with consumers. The process can be aided by WebAPP tools for photo collection and analysis.

Our Ethos

We know the FMCG counterfeiter (20 yrs experience of forensically examining counterfeit products; chemistry of the juice, labels, plastics, metals, cartons etc.)

=> We know how and why counterfeit products are different and how to exploit these differences.

Our Points of Difference

We know the constraints most companies face in the design, manufacture, distribution and selling of FMCG products and the barriers to adding any incremental cost or complexity.

=> Our approach is designed to add negligible cost upcharge/ item and no extra complexity to the manufacturing process.

Colin Peacock and Dr. Jon Stonehouse are both retired senior P&G leaders. Colin built and was the lead for the Global Brand Protection Program during his time at P&G. Jon was 16 years as the technical leader for the program. P&G’s initial zero cost approach was originally designed and implemented under their leadership and developed and delivered through 3rd party collaborations with artwork, coding equipment suppliers/ universities and SMEs.

Who we are

We can enable you to detect a counterfeit from a standard photo from a mobile phone…

… giving you the ability to respond in near real-time to in-market counterfeit issues and much more..

How we do this

Smart Design and systemic implementation of text, image and number steganography features.

Sometimes, closer analysis of the packaging/ product is still needed.

We can advise/ help on this…..

Our Services

Start your journey towards near zero-cost counterfeit detection with a half-day virtual Immersion Workshop

To help you unlock your programme, we offer three levels of consultancy engagement:

Level 1:

We will host a highly interactive half-day virtual event that will equip your multinational teams with the knowledge and tools to strengthen your Brand Protection program.

From this exercise, you will learn how to detect counterfeit products using simple, low-cost techniques, implement anti-counterfeit measures, and leverage internal systems for effective protection and set you on the journey to ZeroCost Brand Protection

The workshop combines real-world insights, demonstrations, and actionable frameworks for immediate implementation, summarized in a report that will be sent shortly after the workshop.

Level 1 is designed to leave you with the knowledge, business connections and some tools to immediately augment your current Brand Protection program to set you on the journey to ZeroCost Brand Protection.

Level 2:

If, after participating in Level 1, you are convinced by our ZeroCost approach to enable you to detect a counterfeit from a photo, we can also offer consultancy help design and implement bespoke approaches for your key brands. This highly interactive workshop will involve a deeper dive into your products (packaging, chemistry, manufacturing etc.), and result in a bespoke set of specific recommendations that fit your product. It will also help you to “reduce to practice” and launch.

Level 3:

Ongoing consultancy/ help to implement and integrate ZeroCost Artwork and Coding strategies with cloud based digital tools.

Ready to Safeguard Your Brand?

Contact us to schedule your private corporate session. Empower your team to identify and combat counterfeiting effectively, efficiently, and affordably.

Meet the Co-Founders

Colin Peacock and Dr. Jon Stonehouse are both retired senior P&G leaders. Colin built and was the lead for the Global Brand Protection program during his time at P&G. Jon was 16 years as the technical leader for the programme. P&G’s initial zero cost approach was originally designed and implemented under their leadership and developed and delivered through 3rd party collaborations with artwork, coding equipment suppliers/ universities and SMEs.

Colin Peacock: Co-founder & Business Development Director of ZeroCost Brand Protection.

Protecting your brands from criminal counterfeiters is a problem for both the court room, as well as the board room but for me, effective brand protection has to start in the boardroom with the active engagement of all parts of the business, marketing, quality control, customer service, R&D, logistics, sales, etc, as well as third parties, such as your production facilities, logistics, distributors, wholesalers, and retailers.

For those leading the brand protection programme, the very first place to start has to be the building of the capability across the business to easily detect fakes, something that we know can be done for near zero cost. We have founded this company to bring this capability to brand owners, to help their business more easily identify their fakes at near zero cost.

Prior to the founding of this company, I had a thirty-year career with P&G, which included a period leading their global brand protection programme. For the last sixteen years, I have been an honorary visiting fellow at the University of Leicester, Department of Criminology and have continued to act as the Group Strategy Coordinator for ECR Retail Loss, a collaborative platform to help retailers and CPG’s find new, imaginative ways to sell more, and lose less, through research and collaboration. I regularly publish new research and write articles that get published in titles such as HBR and have co-authored a book called “New Loss Prevention” with Professor Beck.

Dr. Jon Stonehouse – Co-founder & Technical Services Director of ZeroCost Brand Protection

When I first started helping detect counterfeit products for P&G 20 yrs ago, we had to send any suspect products to our manufacturing plants, a process and timeline that was not good enough to meet in-market needs. My journey since then involved setting up efficient laboratory analysis capability that could manage the complexity of the global product range, evaluating 3rd technology - QR codes, Holograms/ various native APPs etc. and understanding the (mostly) insurmountable challenge of not adding incremental cost or complexity to manufacturing. Ultimately, I realised that we needed to be able to detect a counterfeit product from a simple mobile phone photo and do this in a way that added close to zero incremental cost and complexity to the business, this is the programme that we now want to make available to other brand owners.

Prior to the founding of this company, I worked for 30 years in P&G R&D, including 16 years as the global leader in physical and digital Brand Protection technology innovation. While with P&G, I was the inventor on multiple patents in counterfeit detection and authentication.